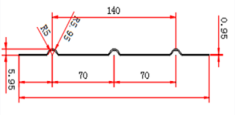

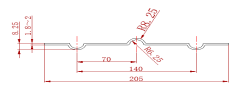

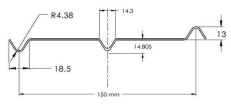

3V Blade for Fire Damper, Fire damper blade

Reference shapes | ||

grooving on same direction | grooving on different direction | grooving on different direction |

|

|

|

(II) Production Flow Processes and Main Features

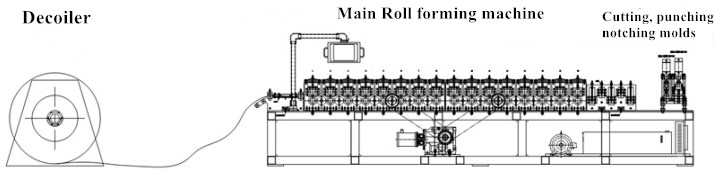

Decoiling → Cold roll forming → Straightening, shaping → Cutting to length, punching → Manual discharge

(III) Components List

1. Two non-powered manual internally-braced feed racks

2. One set of main forming machine

3. One set of cutting, punching and notching molds

4. One set of electric control system

5. One set of hydraulic control system

A 3V blade is a reinforced, roll-formed steel blade design for fire dampers, featuring three longitudinal “V”-shaped grooves that boost rigidity, minimize deflection, and enhance sealing when closed. It is widely used in UL-listed fire/smoke dampers for reliable fire containment and airflow control.

Key Details

Structure: Typically 16-gauge (≈1.5mm) galvanized or stainless steel, with three integral V - shaped ribs for structural reinforcement, preventing warping under high temperatures or airflow pressure.

Function: When the damper closes (triggered by a fusible link), the 3V profile ensures tight blade - to - blade and blade - to - frame contact, reducing smoke/fire leakage and meeting UL 555 (fire) and UL 555S (smoke) leakage classes (often Class I/II).

Performance: Suitable for dynamic (fan - on) and static (fan - off) applications, handling air velocities up to 2000–4000 fpm and pressures up to 4–10 in.w.g., with fire ratings of 1.5–3 hours.

Design Benefits: The V - ribs improve strength without adding excessive weight, enabling efficient manufacturing and consistent performance across rectangular/square duct installations.

Spring Leaf for Fire Damper | Flexible Air Duct Connector | Support Bar for Fire Damper | Rivet Table for Fire Damper |

Fodi Machinery Co.Ltd Development History

★ Profound experience in HVAC Ducting Machinery (Since 1988).

★ Profound experience in Automatic Spiral Duct Forming (Since 2004).

★ Profound experience in Automatic Duct Production Line (Since 2006).

★ Have the largest inventory for HVAC Duct Making machines in the industry.

★Got Pantened for Fire Damper Series

★ The real manufacturer with the most complete varieties of HVAC Ducting Machinery in China.

★★★Fodi company can give you both CNC duct production line machine which can manufacture air duct automatically. We will suggest a whole machines series in accordance with different customers needs★★★

Fire Damper Series Working Site |  |

【 Go Back 】 | 【 Close this window 】