TDF Flange Forming Machine

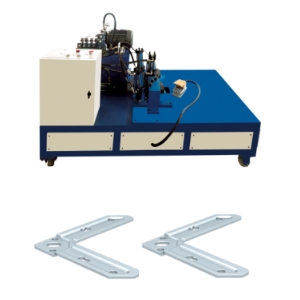

Apply shared-plate flange, therefore, the rectangle ductwork flange can be fast processed.

The machine applies both sides feeding and simultaneously shaping work mode, one

side forming ,and one side forming is for installing hooks

,and one side forming is for installing hooks .It features low

.It features low

making cost and high installing efficiency, convenient for standard and batches of production.

It is suitable for making rectangle wind pipe with big section.

|

|

|  |

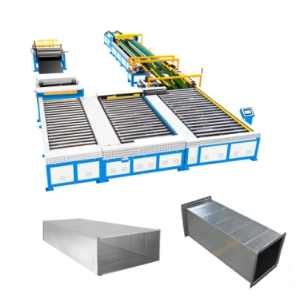

TDF flange forming machine is mainly used to produce square and rectangular air ducts and self-made semi-finished TDF flanges. It can also be used to create finished ducts by combining it with a duct production line, cutting machine, bending machine, locking machine and corner code machine.

Our company offers two types of TDF flange forming machines: T12 and T15. The thickness of the formed iron plate varies from 0.5mm to 1.5mm. These machines are ideal for on-site manufacturing of ventilation exhaust ducts in industries such as mining, hotels, shopping malls and construction due to their compact size, lightweight design, ease of movement, adjustment, ease of operation and reliability.

Following are use case diagrams.

Here are the drawings:

TDF flange installation

Basic Parameters

Components of TDF flange forming machine: The machine consists of a rack, a transmission component, a flange forming component, a hook forming component and a power component (motor and reducer).

Overall dimensions: The machine measures 2,700 mm long, 700 mm wide and 1,100 mm high.

Weight: The machine weighs approximately 850 kilos.

Reducer model: The machine uses an RV110 reducer with a gear ratio of 25-30.

Engine power: The engine has a power of 3 kW.

Applicable material: The machine is designed to work with common galvanized plates with a thickness of 0.6mm to 1.2mm.

Working Speed: On average, the machine operates at a speed of about 14 meters per minute.

Length limitation: There is no limit to the length of material that can be processed by the machine.

Product accuracy: The size error does not exceed ±0.6mm and th

Air Duct Automatic Production Line VIII |  Air Duct Flange Corner Installation Machine |  Air Duct Seam Locker Machine |  TDC Duct Flange forming machine |

Fodi Machinery Co.Ltd Development History

★ Profound experience in HVAC Ducting Machinery (Since 1988).

★ Profound experience in Automatic Spiral Duct Forming (Since 2004).

★ Profound experience in Automatic Duct Production Line (Since 2006).

★ Have the largest inventory for HVAC Duct Making machines in the industry.

★Got Pantened for Fire Damper Series

★ The real manufacturer with the most complete varieties of HVAC Ducting Machinery in China.

★★★Fodi company can give you both CNC duct production line machine which can manufacture air duct automatically. We will suggest a whole machines series in accordance with different customers needs★★★

【 Go Back 】 | 【 Close this window 】